What is the production process of chemical materials?

The production process of chemical materials usually includes main steps such as raw material preparation, chemical reactions, separation and purification, product molding and packaging. However, the production process of different types of chemical materials may vary. The following is a general introduction to the production process:

raw material preparation

Raw material procurement and inspection: Based on production needs, various basic raw materials are purchased, which may include oil, natural gas, coal, ore, agricultural products, etc. Strictly inspect the purchased raw materials to ensure their quality and purity meet production requirements. Testing indicators include composition, content, impurity content, physical properties, etc.

Raw material pretreatment: Pre treat raw materials to meet the requirements of subsequent production processes. Common preprocessing methods include crushing, grinding, sieving, mixing, drying, purification, etc. For example, ore raw materials need to be crushed and ground to achieve a suitable particle size range for subsequent chemical reactions; Liquid raw materials may require purification operations such as distillation and extraction to remove impurities.

chemical reaction

Reaction condition setting: Determine appropriate chemical reaction conditions based on the production process of chemical materials, including temperature, pressure, catalyst, reaction time, etc. The precise control of these conditions is crucial for the progress of the reaction and the quality of the product. For example, in the production of synthetic ammonia, it is necessary to react nitrogen and hydrogen under high temperature, high pressure, and the action of a catalyst to generate ammonia.

Reactor selection and operation: Choose the appropriate reactor type based on the characteristics and requirements of the reaction, such as kettle reactor, tubular reactor, fluidized bed reactor, etc. Add the pre treated raw materials into the reactor in a certain proportion to initiate the reaction process. During the reaction, real-time monitoring and control of reaction parameters are required to ensure that the reaction proceeds according to the predetermined path and prevent side reactions or safety accidents.

separation and purification

Preliminary separation: After the reaction is complete, the resulting product is usually a mixture containing the target product, unreacted raw materials, by-products, and impurities. Firstly, preliminary separation is carried out using commonly used methods such as filtration, centrifugation, and sedimentation to separate solids and liquids, as well as mixtures between liquids. For example, solid catalysts or insoluble impurities in the reaction products can be removed through filtration.

Fine purification: In order to obtain high-purity chemical materials, fine purification operations are required. Common purification methods include distillation, rectification, extraction, adsorption, crystallization, etc. Distillation and rectification are commonly used to separate liquid mixtures with different boiling points. Based on the boiling point differences of each component, the target product is separated from other components through heating and condensation processes; Extraction is the process of utilizing the solubility differences of solutes in different solvents to transfer the target product from one solvent to another, achieving separation and purification.

Product Forming and Packaging

Product molding: Based on the purpose and market demand of chemical materials, the purified product is processed into a molded form. For example, for plastic pellets, molten plastic is made into pellets through processes such as extrusion granulation, for storage, transportation, and subsequent processing; For powdered chemical products, drying, sieving, and other operations may be required to achieve the specified particle size and shape.

Quality inspection: Before packaging the product, a comprehensive quality inspection is conducted again to ensure that the product meets relevant quality standards and customer requirements. The testing items include chemical composition analysis, physical property testing, purity testing, particle size distribution determination, etc. Only products that pass the inspection can enter the packaging process.

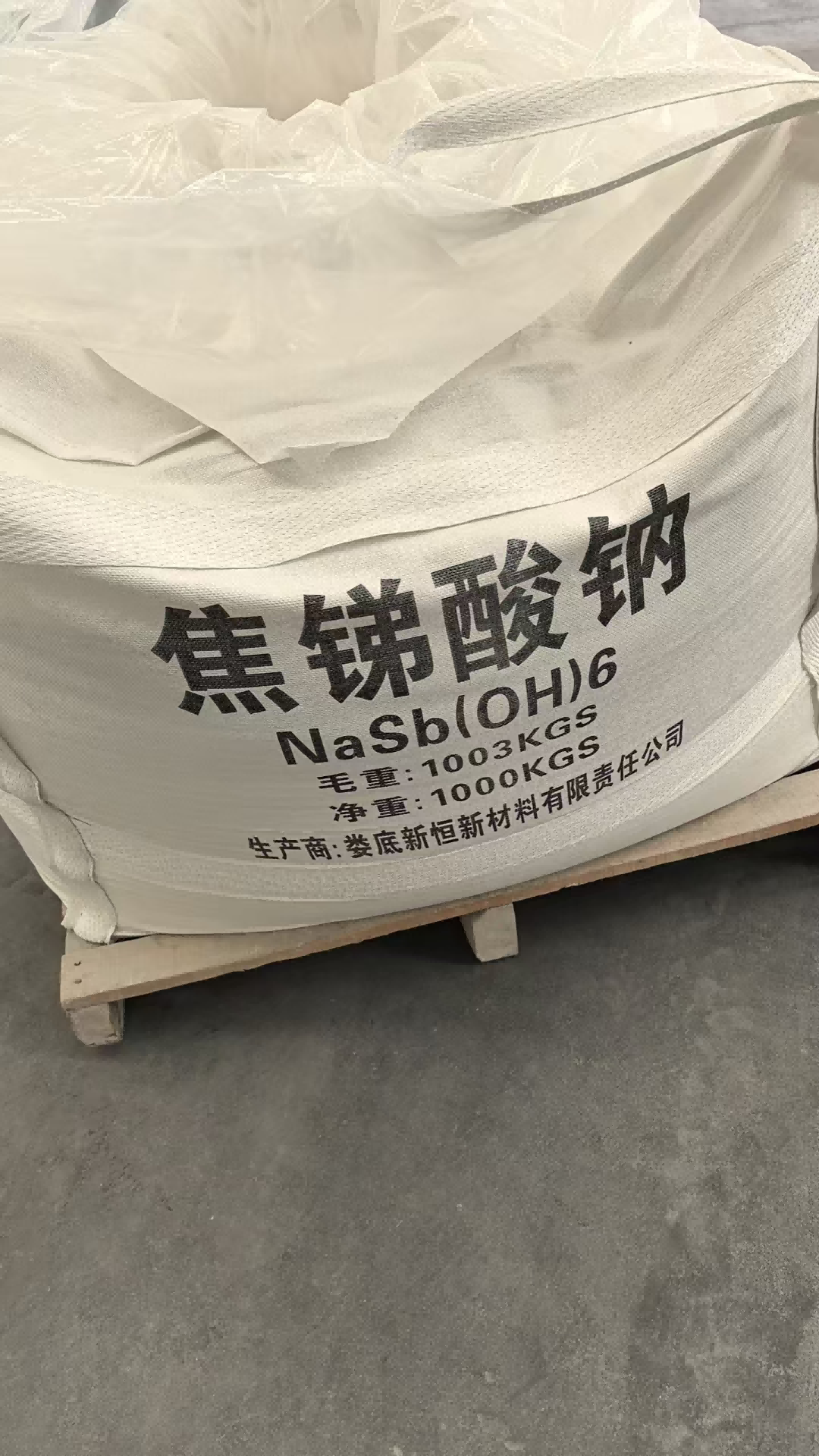

Packaging and Storage: Choose appropriate packaging materials and forms based on the nature of the product and customer needs, such as bagged, barreled, bottled, etc. Label the packaged products with information such as product name, specifications, batch number, production date, shelf life, etc. Then store the products in a suitable warehouse, control the temperature, humidity and other environmental conditions of the warehouse according to the storage requirements of different products, and ensure the stable quality of the products during storage.

Please first Loginlater ~